What is In-Vessel Composter? Utilization of In-vessel Composting System?

The in-vessel composter is a kind of totally-closed, vertical type compost fermentation equipment, being an air-clean anaerobic fermentation system. It is widely used for processing organic wastes into organic fertilizer, suitable for various organic waste, such as animal manure (pig manure, chicken manure, cow dung), agricultural waste, livestock waste, kitchen waste, municipal sludge, industrial waste, mushroom residue, crop straw, etc.

Find more information on compostable organic materials here.

Compared to the windrow composting method, if there is little available land for composting projects, the In-vessel composter is a better choice to realize the utilization of waste resources for livestock breeding, medium and large farms, circular agriculture, ecological agriculture, etc.

In-Vessel Composting Process

In-vessel composter adopts the microbial aerobic fermentation that microorganisms can make full use of organic matter and residual protein in animal manure, and reproduce rapidly under certain conditions of temperature, humidity, and sufficient oxygen. During the reproductive processes, microorganisms consume the organic matter, protein, and oxygen of the manure, thus metabolizing into ammonia, CO2, and water vapor. Meanwhile, a large amount of heat is released that can raise the temperature of the tank.

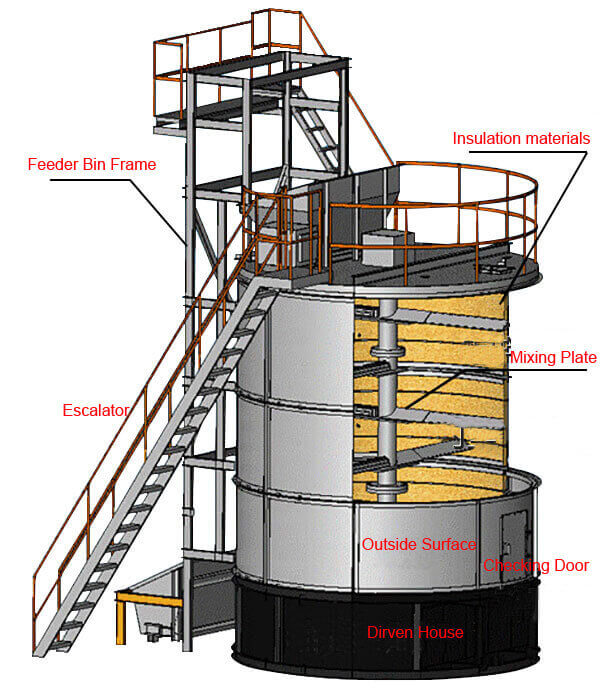

It is mainly composed of the fermentation chamber, hoisting system, high-pressure air supply system, drive system, hydraulic power system, deodorization system, discharging system, and automatic control system. Adopt PLC programmed control, and the process of feeding, fermentation, temperature control, and discharging is automatically completed.

The process flow mainly includes the following steps :

Mixing→Conditioning→Feeding→Fermentation→Discharging

◆ Mixing Part

Mix the animal manure or organic waste (water content is about 75%) with biomass, and ferment bacteria in a certain proportion. Adjust the moisture content, C:N ratio, and air permeability to meet the fermentation conditions. If the moisture content of raw material is about 55-65%, the organic waste can be fermented directly in the tank.

◆ Fermentation Part

The fermentation process can be divided into three stages, which are: the rapidly rising temperature stage, the high-temperature stage, and the cooling stage.

When the decomposition speed becomes slow, the temperature will gradually decrease below 50℃. The whole fermentation process lasts for 7-15 days. The waste gas and water vapor are treated by the deodorization system and discharged through the discharging system, thus reducing the volume of the organic fertilizer and reaching the treatment of reduction, stabilization, and harmlessness.

When the fermentation is completed, the fermented material will fall down under the function of stirring force and gravity, then be discharged as the organic fertilizer.

The organic fertilizer processed by the in-vessel composting method fully conforms to the national standard.

Here are two tables showing the testing result of organic fertilizer produced by the in-vessel composter.

Test Data of Organic Fertilizer Made by Chicken Manure

| Item | Test Data | Test Result |

| H2O | 25.32% | ≤30 |

| T-N | 2.65% | ≥5.0 |

| P2O5 | 6.62% | |

| K2O | 3.25% | |

| pH | 8.1 | 5.5-8.5 |

| Organic Material | 62.91% | ≥45 |

| As | ≤4.9 | 30mg/kg |

| Cd | ≤0.6 | 3mg/kg |

| Pb | ≤0.56 | 100mg/kg |

| Cr | ≤32.3 | 300mg/kg |

| Hg | ≤0.07 | 5mg/kg |

Test Data of Organic Fertilizer Made by Pig Manure

| Item | Test Data | Test Result |

| H2O | 25.32% | ≤30 |

| pH | 8.42 | 5.5-8.5 |

| Organic Material | 57.3% | ≥45 |

| N | 2.32% | / |

| P2O5 | 4.72% | / |

| K2O | 2.64% | / |

| N+P2O5+K2O | 9.68% | ≥5.0 |

| Cd(mg/kg) | 0.5 | ≤3 |

| Cr(mg/kg) | 30.8 | ≤150 |

| Pb(mg/kg) | 0.6 | ≤50 |

| As(mg/kg) | 5.5 | ≤15 |

| Hg(mg/kg) | 0.08 | ≤2 |

Advantages of Vertical In-Vessel Composting Equipment

▼ High resources conversion rate (90%): The highest conversion rate of organic compost can reach 90% of the amount of organic waste.

▼ It adopts high-temperature fermentation technology–stable running, low consumption, low running cost. The temperature in the in-vessel composter can reach 80-100℃, which could kill the harmful bacteria thoroughly. organic matter in waste is biodegraded and decomposed by using microbial activity so that organic waste can be processed into organic fertilizer, achieving the resource utilization of organic waste.

▼ The in-vessel composting system avoids the problems of traditional windrow composting, such as low composting temperature, short duration of high temperature, long period of composting, environmental pollution and poor sanitation, etc.

▼ Turning waste into treasure, no secondary pollution. The bio-treatment device carries out harmless treatment of organic waste in the production process. Waste gases treated by a deodorization system can reach discharging standards.

▼ Well-knit structure, less land occupation, convenient installation, reducing floor space of equipment. In-vessel composting equipment only covers 10-30 square meters. A high level of automation can be operated by one person, saving labor with the installation of a high-efficiency PLC programmed control system.

▼ In-vessel composter uses high-property polyurethane heat preservation material, of which temperature is less affected by outside, ensuring normal operation at all seasons. And auxiliary heating ensures the normal operation of the machine at low temperatures. It is equipped with a mixing system that can mix the raw materials periodically with good mixing and fermentation effect. Productivity has risen greatly, and fermentation time is greatly shortened.

PS: It is suitable for mixing powder and liquid materials with various ingredients. It has the advantages of wide applicability, good mixing uniformity, less material residue, and convenient maintenance, which is the ideal equipment for treating various organic wastes.

▼ The body of the vertical in-vessel composting system adopts total stainless steel, corrosion resistance, and long service life. It adopts a hydraulic drive system that can guarantee full load operation of the fermenter and realize online cleaning and sterilization.

Specification and Daily Treatment of In-Vessel Composting Equipment

| MODEL | TC-8A | TC-40A | TC-61A | TC-90A | TC-101A | TC-200A | |

| Volume (m3) | 8 | 40 | 61 | 90 | 101 | 200 | |

| Power (kW) | 4.9 | 18.2 | 27.3 | 37.7 | 37.7 | 72.3 | |

| Land Occupation (m3) | 20 | 66 | 66 | 96 | 96 | 176 | |

| Chicken Manure

(Water Content 60%) |

Treatment Quantity (t) | 1.7 | 6 | 8 | 12 | 13.5 | 25 |

| Discharge Quantity (t) | 0.6 | 2.2 | 3 | 4 | 5 | 11.8 | |

| Pig Manure

(Water Content 78%) |

Treatment Quantity (t) | 1.3 | 4.5 | 6 | 9 | 10 | 17 |

| Discharge Quantity (t) | 0.3 | 0.9 | 1.2 | 1.8 | 2 | 3.3 | |

| Cattle Manure (Water Content 85%)

+ Auxiliary materials |

Treatment Quantity (t) | 0.9 | 2.6 | 5.2 | 7.5 | 8.5 | 15 |

| 0.2 | 0.6 | 0.8 | 1.2 | 1.3 | 2.2 | ||

| Discharge Quantity (t) | 0.3 | 1.3 | 1.6 | 2.3 | 2.8 | 4.2 | |

| Kitchen Waste (Water Content 80%) | Treatment Quantity (t) | 0.9 | 4 | 5.5 | 7 | 8.5 | 15 |

| Discharge Quantity (t) | 0.2 | 0.6 | 0.8 | 1.2 | 1.1 | 1.9 | |

| Sludge (Water Content 80%) + Auxiliary materials | Treatment Quantity (t) | 0.5 | 2.5 | 3.5 | 4.5 | 5 | 10.5 |

| 0.1 | 0.6 | 0.8 | 1.2 | 1.5 | 2.5 | ||

| Discharge Quantity (t) | 0.2 | 0.6 | 1 | 1.5 | 1.7 | 3 | |

PS: We can customize in-vessel composting equipment with different capacities and different forms (horizontal, vertical) according to customers’ demands.