Elevating belt compost turner offers a turning capacity of 300-450 cubic meters per hour, with a heap height of 4.3m. It has similar advantages as groove type compost turner and hydraulic compost turner that helps process organic waste quickly and efficiently, but with a totally different working principle and parts from other composting equipment.

We offer a full line of compost turners, rotary screens, and compost grinders to help improve productivity and streamline maintenance.

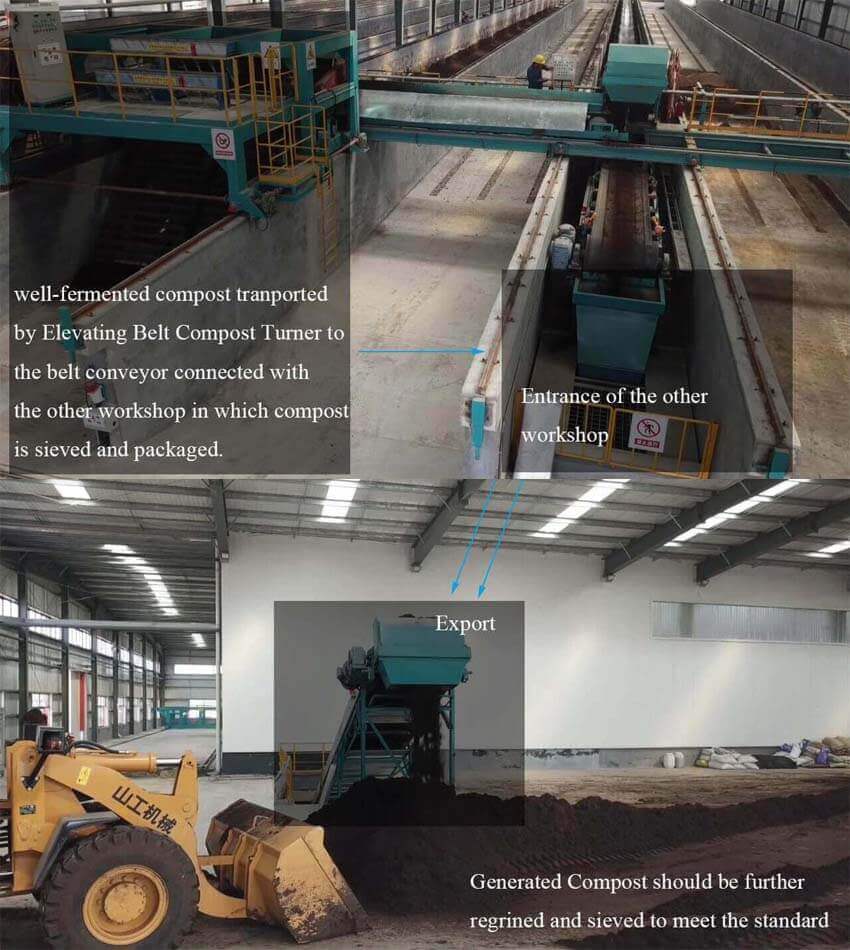

Elevating Belt Compost Turning Process:

The first stage–grinding and piling:

Piling: Compostable raw materials, such as sludge, municipal organic waste, poultry litter, chicken manure, swine manure, cow dung, etc. are loaded into bunkers separated by concrete walls (left). Composting is done in bunkers with our chainplate compost turner system. The amounts of bunkers to be built depends on the quantities of raw materials to be decomposed.

The second stage–composting:

Working process: as the turner moves forward, the conveyor lifts the organic up the face and drops them off the back into the window, which allows for good size reduction, aeration, and mixing. Its role is to turn the material from the existing windrow through and drop them back into the turner machine to construct a new window as the material falls in the same bunker. It breaks the pile up with each turn.

The last stage–sieving:

More Details about Elevating Belt Compost Turner:

◇ It is usually mounted on the front of a wheel loader and powered by the loader’s hydraulic power transmission system that pushes the turner through the windrow or pile.

◇ It is with an automatic drive for track operation, often used in under-house channel composting (moving the composting material along the channel with each turning) in the agricultural-animal raising field/poultry operations for fly control and mixing and composting animal wastes, and made for many different size facilities–small- and medium-sized plants.

◇ Elevating the belt compost turner minimizes aisle space. It shifts the materials from the front to the back and can turn an entire windrow, nearly eliminating the need for space between windows.