Main Ingredients

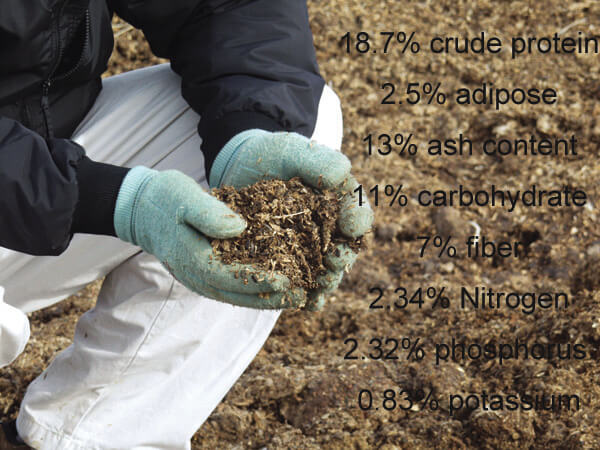

Chicken manure is rich in nutrients, such as 18.7% crude protein, 2.5% adipose, 13% ash content, 11% carbohydrate, and 7% fiber, including 2.34% Nitrogen, 2.32% phosphorus, and 0.83% potassium, which respectively are 4.1 times, 5.1 times and 1.8 times of pig manure.

Physiological Characteristics of chicken

Without fully digestive absorption of the intake of chicken feed, there are about 40%-70% of nutrients excreted, so the nutrient of fowl manure is the highest among all feces of livestock and chicken. However, there will be great harm and hidden troubles if the chicken manure is directly applied in the crop field without appropriate handling and decomposing. For example, using the chicken manure directly in the soil may create an amount of heat under proper conditions, which can burn the entire crop root. In the meantime, there are a lot of germs and pathogens in the chicken manure, also bringing some harmful effects to crops. Therefore, it’s very necessary to apply the chicken manure only after harmless treatment and full decomposition.

The traditional way is sealing the chicken manure for retting and anaerobic fermentation, which always takes 3-4 months for full decomposition. Nowadays, with the rapid development of biotechnology, adopting aerobic fermentation, the speed of decomposing is 10-20 times faster than the traditional method. By this means, the macromolecule of chicken manure, like protein, will be decomposed into micro molecules so that the nutrition content can be directly absorbed by crops. During the aerobic fermentation process, the organic materials produce ammonia gas, which is harmful to the environment, while, after well-composing, the ammonia gas is biologically removed and deodorized.

Characteristics of Chicken Manure

The main material of chicken manure is organic matter that can raise the organic content in the soil. chicken-dung performs well as a fertilizer rather than soil ameliorant and is self-rich in site fertility, while the most important thing is that organic matter can improve soil properties in aspects of physical, chemical, and biological, and fertilizing the immature soil. There is an old saying related to chicken manure, that is, “soil feed depending on dung while crops grow counting on dung”, which, to a certain extent, reveals the effects of soil reclamation by using chicken manure. Using chicken manure cannot only add lots of organic colloids but also decompose many organic matters into organic colloids in virtue of microbial action, which greatly expands the adsorption surface of the soil and generates a lot of sticky matters. So soil particles become stable granular structures via conglutination, improving the soil property of water retention, fertilizer conservation and ventilation, and the ability to regulate the temperature of the soil.

Chicken Litter Feed

★ The social value of chicken litter feed

As is well-known, the intestinal canal of chicken is too short to fully digest the fodder they intake, therefore, the amount of nutrition content is excreted along with its excrement. The nutrient content of chicken manure has some relation to the growth period and economic use of chicken. Taking the broiler chicken and laying hen, for example, the dung of broiler chicken contains higher nutriment because of higher energy and higher protein feeding, while the dung of laying hen has high calcium level. As the statistic shows, each laying hen can defecate about 36.4kg per year, while each broiler chicken can defecate about 4.09kg within one or two months, and a grown-up chicken can defecate about 100g per day. Statistics from the UN Food and Agriculture Organization show that dried dung of laying hens contains about 25% crude protein that is 2.94 times of corns, 5% calcium, and 2.1% phosphorus, and chicken manure also contains 18 kinds of amino acids, abundant microelements, and vitamin, especially rich in vitamin B12, which is unparalleled for grain feed.

Where there is chicken manure, there are flies. The amount of chicken manure piled up in one place can not only harm the environment but also waste resources. Many farmers see chicken manure as a waste to eliminate. However, when chicken feeding gets to a certain scale, the treatment and utilization of chicken manure will become very important. The chicken manures are not only great fertilizers but also can be used as fodder due to the higher nutritive value. The comprehensive utilization of chicken manure could greatly improve the sustainable natural environment, eliminate the flies and mosquitoes as well as the odor, and reduce disease transmission, turning waste into treasure and bringing better social, ecological, and economic benefits.

When it comes to the treatment of chicken manure, there are a lot of ways, such as chicken manure fermentation, chicken manure drying, Silage method, chemical treatment, thermal spraying, etc. And the most applicable way for common users is chicken manure fermentation for its simple process and low cost.

Fermentation of Chicken Manure

The traditional way of chicken manure fermentation is natural heap fermentation for 5 to 6 months, but the terrible odor diffuses, polluting the environment as well as leading to nutrient loss. While compared with this fermentation, microbe fermenting is more efficient, which can not only expedite the fermentation process, shorten fermenting time, avoid waste, and promote the nutrient value of chicken manure, but also considerably save the energy consumption by drying the chicken manure through high temperature from fermentation. In virtue of its simple operation, easy promotion, and low cost, this fermentation method has been attached to great importance by people.

★ Tools: mixer, plastic container or cement pit (or pit with plastic membrane), plastic membrane, and grinder.

★ Fermentation bacteria: chicken manure leavening agent

★ The raw material is chicken manure, divided into dried chicken manure and fresh chicken manure. Now, let’s talk about the fermentation method as follows:

Fermentation method of dried chicken manure:

Due to the lack of water, adequate water should be added to dried chicken manure, then piled up for fermentation.

The formula I: 1000kg dried chicken manure, 0.25kg leavening agent bacteria of chicken manure.

Fermentation method of fresh chicken manure:

For fresh chicken feces, some auxiliary materials should be added when fermenting so as to absorb moisture from the chicken manure. Too much water will cause impermeable effects and inhibit the fermentation of the microorganism. There are a great diversity of auxiliary materials to choose from, aiming at absorbing water from chicken manure. In general, auxiliary materials refer to saw powder, straw, peat carbon, and so on. The adding proportion is about 70% chicken manure and 30% auxiliary materials, and the proportion can be adjusted according to the soil quality and nutrition content. If as the fertilizer for orchards or as animal feed, the bacteria seeds, widely sold on the bacteria seeds market, also need to be added. The ratio of fermentation raw materials is about 70% fresh and healthy chicken manure, 15% corn starch, 10% cavings, 5% wheat bran, and 1‰ feed leavening agent, stirring them thoroughly, and then adding some water, and making sure that water content controlled in 65% or so because it’s adverse for moisture content neither excessive nor low.

Formula II: 700kg wet chicken manure, 300kg gluten, paddy bran or straw power, 0.25kg leavening agent bacteria of chicken manure.

Operation as follows:

★ Prepare the raw material of fermentation according to the appropriate ratio, serving for the raw material of fermentation.

★ Pour 0.25kg fermentation bacteria into the water for attenuation, and stir evenly, and it’s better to use the well water or river water when thinning, and stirring for 10-30 minutes.

If there is a mixer, one can stir the chicken manure for two minutes, then add the bacteria seeds to dilute and stir them for 6 minutes. While if no mixer, stir them with a spade according to the principle of from less to more, that is, pour the bacteria seeds diluent into bit ferment raw materials and stir thoroughly until there are no agglomerations, and then add the well-stirred ferment raw material into the remaining fermentation raw materials and stir evenly until there are no agglomerations; and adding fermentation bacteria into raw material and stir them uniformly, and pile them up with about 1m height, 1.5m-2m width and unlimited length. The moisture should be controlled at 40% or so (Notice: the dilution water amount should be added depending on the drought-wet degree of fermentation raw materials. The dilution water of bacteria seeds should be about 35% – 40% of fermentation raw materials, stirring until no droplet when scrunching up and dispersing once loosening grip. Attention: it’s easy to be acescent if more water while incomplete to ferment if less water. If fermentation raw materials are wetter, the dilution water should be reduced.); and then perforate on the heap top for ventilation; finally use a rectangular plastic cloth to cover the fertilizer heap, and press the plastic cloth on the ground with heavy stuff per meter, which makes it ventilated and also avoid swell by high wind.

★ Fermentation time: more than one month in winter while about 14-21 days (1-2 periods) in summer. The application of compost turner will largely shorten the whole fermentation time. For large-scale chicken manure composting sites, compost turner machines are inevitable equipment in the whole decomposition process.

Application of Chicken Manure Compost:

- Available for breeding fish and shrimps without polluting water, serving as fish and shrimps feed as well as fertilizer products.

- Available for breeding yellow mealworms, fly maggots, and earthworms, establishing an ecological breeding model.

- Available for producing bio-organic fertilizer for flowers and plants.

- Fully-fermented chicken manure compost also can be granulated into biofertilizer granules for sale. This is also the reason why commercial compost turners should be equipped in large-scale organic fertilizer production lines!

Integrated Utilization of Chicken Manure

The comprehensive utilization of chicken manure could greatly improve the sustainable natural environment, eliminate the flies and mosquitoes as well as the odor, and reduce disease transmission, turning waste into treasure and bringing better social, ecological and economic benefits. All chicken-raising regions can adjust measures to local conditions and choose several methods to implement.

- Composting Fermentation

The chicken dung through composting fermentation is a kind of good fertilizer for grape, watermelon, fruit trees and vegetables. It’s great to choose a place with good air ventilation and high altitude, especially to find a place far away from the residential area and at the downwind about 500 meters of the hen house, and pile up the chicken manure with padding after cleaning out, and sealing outside with slurry. Fermenting time is usually about 10 days in summer while 2 months or so in winter.

- Silage Ammoniation

After ensiling, the fresh chicken manure can be used as feed to breeding cattle, sheep, or pigs. Mix the fresh chicken manure with chopped forage, fruit and vegetable waste, potato, sweet potato plants and grain to silage, thereinto silage with non-leguminous forage is best. When silaging, 40%-75% water content should be kept, and corn could be added, and appropriate hydroxide should be added in order to increase the digestibility and palatability of chicken manure storage. After drying fresh chicken manure, put the chicken manure into green maize and ensilage at a ratio of 30%, and then use them to feed cattle, which has higher crude protein content and could be almost comparable with soybean and corn.

- Air-dried Pulverizing

Spread the fresh chicken manure in the plastic shed for air-cure with dung thickness less than 15cm, and stir them with a spike-tooth harrow and blow with high-speed blower. The dried chicken manure can be processed into diet pellets to feed cattle, sheep, and chicken, and the addition level is often less than 20%.

- Direct feeding method

Fresh chicken manure can be directly used to feed the pigs and fish, adding appropriate levels according to the different chicken manure and different efficient ingredients. For example, the dung of young chicken has higher protein that can be used for concentrated feed, while the dung of laying hen contains more ash content. When feeding pigs, directly add fresh pure chicken manure into pig feed at a ratio of 15% per day, and one pig can averagely consume about 8-10 adult chicken droppings. When feeding fish, add them directly into ponds.

- Biogas Fermentation

As one of the raw materials of biogas fermentation, chicken manure, especially chicken manure with water, can be used for producing biogas. By building a middle-small size fermenting tank, biogas can be produced after 10-20 days of fermentation. As people know, biogas can be used for life heating, in addition, the biogas residues can be used as fish bait or fertilizer.

Extension Reading:

★ How to compost pig manure?

★ How to compost cow dung?