Keywords 1:

sewage sludge composition, sewage sludge organic matter, sewage sludge organic matter content

Sewage Sludge and its Organic Matter Content

With wastewater treatment increasing, it creates another material to deal with: sewage sludge or municipal sludge. It is a dilute suspension of solids that have been captured by the treatment process. Annually, large amounts of sewage sludge are produced in the process, especially in high and middle-income countries with high treatment coverage. As reported, the total amount of sewage sludge has increased from 7.2 million tonnes of dry matter in 1998 to at least 9.4 million tonnes in 2005.

Estimated sewage sludge production

| Country | Estimated sewage sludge production (dry metric tons) | Population |

| China | 2,966,000 | 1,313,974,000 |

| Italy | 1,000,000 | 58,134,000 |

| USA | 6,514,000 | 298,444,000 |

| United Kingdom | 1,500,000 | 60,609,000 |

| Germany | 2,000,000 | 82,422,000 |

Fresh and untreated sludge will have many pathogens, a high proportion of water, high biochemical oxygen demand and is normally putrid and odorous. Nevertheless, sludge also contains essential nutrients for plants (e.g. Nitrogen and phosphorus) and is potentially a very beneficial fertilizer.

Typical properties of untreated and digested sewage sludge

| Item (% dry weight) | Untreated primary sludge | Digested primary sludge | ||

| Range | Typical | Range | Typical | |

| Total dry solids | 2-8 | 5 | 6-12 | 10 |

| Volatile solids | 60-80 | 65 | 30-60 | 40 |

| N | 1.5-4.0 | 2.5 | 1.6-6.0 | 3.0 |

| P2O5 | 0.8-2.8 | 1.6 | 1.5-4.0 | 2.5 |

| K2O | 0-1 | 0.4 | 0-3 | 1 |

| pH | 5-8 | 6 | 6.5-7.5 | 7 |

When properly treated and processed, sewage sludge becomes biosolids which are nutrient-rich organic materials produced from wastewater treatment facilities. The organic carbon in the sludge, once stabilized, has also potential as a soil conditioner because it improves soil structure for plant roots.

Keywords 2:

sludge composting, sewage sludge composting process, municipal sludge treatment methods

How to Properly Treat Wastewater Raw Sludge?

As mentioned previously, wastewater raw sludge is rich in organic matter, nitrogen, phosphorus, calcium, magnesium, sulphur and other micro-elements necessary for plants and soil fauna to live, so it is characterized by the large manurial and soil-forming value. But sewage sludge should be completely and properly processed before being used in agriculture.

Here are the treatment methods:

1st Stage: Wastewater→Biosolids

Once properly treated, sewage sludge is called biosolids and if safe can be marketed for beneficial uses e.g. in landscaping. Biosolids are semi-solid or liquid materials resulting from the treatment of municipal sewage that has been sufficiently processed to permit these materials to be land-applied safely.

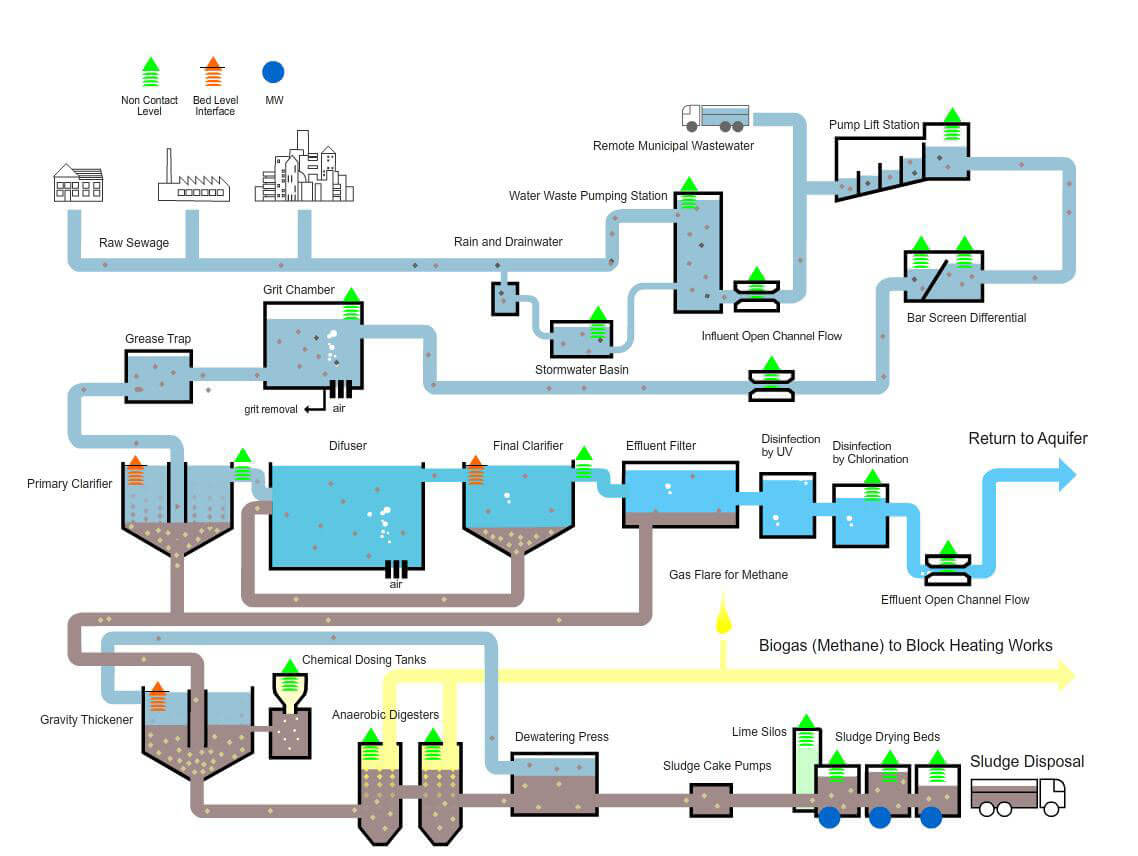

Wastewater treatment process:

primary treatment (removes solids by settling), secondary treatment (biological treatment removing dissolved and colloidal compounds measured as biochemical oxygen demand), disinfection ( to kill microorganisms that might be health hazards) and finally, sludge treatment.

Sludge, the byproduct of the treatment process, is digested for stabilization and is then dewatered for easier handling.

Sludge treatment process:

thickening (force separation of water and solids by gravity, flotation, or centrifugation, the Water content in raw sludge is as high as 98% which makes it unsuitable for composting and makes handling and transport difficult and costly. With sludge thickening in a sedimentation pond water content can be lowered up to 90%), digestion (placing sludge in digesters to converse organic matter to carbon dioxide, water, and methane), dewatering ( reducing the liquid volume of sludge by about 90%).

The resulting material, known as biosolids, is then applied to land to improve vegetation or processed further as compost or fertilizer.

The Municipal Sludge-to-Biosolids Treatment Process

2nd Stage: Biosolids/Sewage Sludge→Compost

Composting is a viable, beneficial option in biosolids management. It is a proven method for pathogen reduction and results in a product that is easy to handle, store, and use. Biosolids/ sewage sludge composting technology is typically done at higher temperatures (55℃) which imitates an accelerated natural process that takes place on the open floor where the organic materials (leaf litter, animal wastes) are broken down. Resulting in an overall reduction of volume, or conversion to more stable organic materials.

It is a complicated process aimed at:

– the destruction of pathogenic organisms;

– stabilization of organic matter

– ripening;

– drying of the sludge;

– production of material that can be environmentally used or sold.

Sewage Sludge/Biosolids Windrow Composting Technology

◆ mixing biosolids with agricultural byproduct sources of carbon such as sawdust, straw, or wood chips to promise the C:N ratio being 25:1/30:1

Notice: other bulking agents suitable for biosolids composting include: shredded tires; crop residues; animal manure and bedding; yard trimmings; food by-products; industrial by-products from wood processing, forestry, brewery; paper goods, paper mill residues, and biodegradable packaging materials; municipal solid waste

◆ piling them in long rows/windrows

◆ mechanically turning biosolids to increase the amount of oxygen using a hydraulic windrow turner or self-propelled compost windrow turner that straddles the composting piles

◆ regulatory requirements: 50-55℃ for at least 15 days with 5 turns

Some other parameters affecting the quality of sewage sludge compost:

| Moisture Content | The moisture content of dehydrated sludge is 80%, Before sending it into the fermentation tank, adjust water content to 50% -60% and rot organic matter content to less than 35%. |

| Ventilation Rate | At the beginning of fermentation, adopt forced ventilation. Ventilation: 0.2-0.6m3 / (t/min).

PS: Stiff materials like corn cobs, nutshells, shredded tree-pruning waste, or bark from lumber or paper mills better separate sludge for ventilation than softer leaves and lawn clippings |

| Fermentation Room State | In the fermentation of materials, through the high-temperature phase until the stack temperature drops to 40 ℃, turn off the fan regulating damper, so that the fermentation tank is in a closed state.

PS: Temperature is an important factor in microbes’ livingness and compost process. It is one of the most parameters during the operation of controlling compost. |

| Fermentation Time | The fermentation time is about 5-7 days under high temperature and aerobic fermentation, and 8-10 days after aerobic incubation. The whole aerobic fermentation period is 13-17 days. |

Keywords 3:

sewage sludge compost, sewage sludge as organic fertilizer, sewage sludge fertilizer

Popularity of Sludge Composting, and Reasons

Sludge composting is an indirect use of municipal sludge in agriculture, which is a widely used method in the treatment of municipal sludge. After composting, the pathogens are killed and the structure of sludge is loose. When it reaches the degree of maturity, there were is no mosquitoes. The nutrients, such as nitrogen, phosphorus and potassium, are also increased.

Benefits of sewage sludge compost:

◆ sewage sludge compost provides large quantities of organic matter and nutrients (such as nitrogen and phosphorus) to the soil.

◆ sewage sludge as organic fertilizer improves the soil agglomeration and soil texture, increases plants’ output, and elevates soil exchange capacity, all characteristics of good organic fertilizer.

◆ biosolids compost is safe to use and generally has a high degree of acceptability by the public, making it a good alternative to other bulk and bagged products available to homeowners, landscapers, farmers, and ranchers.

The United Kingdom, France, Germany and other developed countries, also have sludge composting fertilizer for sale. Eastern treatment plant in Melbourne of Australia treats 1.2×104m3 dry sludge per year as soil amendments to sell to the nursery. In China, Shenzhen has mixed sludge composting and animal manure for sale. According to the nutrient content of sludge compost, soil nutrient status, and plant’s nutrient demand, add a certain amount of chemical fertilizer and microelements to make compound-organic sludge composting fertilizer. Applying for rice cultivation can increase rice yield by 11.4%.

Biosolid composting has grown in popularity for the following reasons:

• Lack of availability of landfill space for solids disposal;

• Composting economics are more favorable when landfill tipping fees escalate;

• Emphasis on beneficial reuse at federal, state, and local levels;

• Ease of storage, handling, and use of the composted products;

• Addition of biosolids compost to soil increases the soil’s phosphorus, potassium, nitrogen, and organic carbon content.