Generally speaking, there are three sources of municipal solid waste.

◎Domestic solid waste comes from households and public areas, including waste collected from residential buildings, litter bins, streets, marine areas, and country parks.

◎Commercial solid waste comes from shops, restaurants, hotels, offices, and markets in private housing estates.

◎Industrial solid waste is generated by all industries but does not include construction and demolition waste, chemical waste, or other special waste.

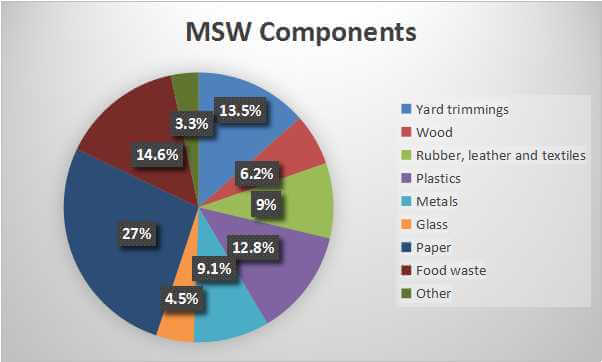

At the present, MSW management arouses the interest, which builds on successful treatment with compost yard trimmings, agricultural wastes, and sludge. One of the effective treatments is to compost municipal solid wastes. As is known to all, due to MSW containing materials that vary widely in size, moisture, and nutrient content, disposal of municipal solid waste requires a series of treatment processes which include collection, contaminant separation, sizing and mixing, and windrow composting.

The first step: municipal solid waste sorting (garbage sorting equipment) MSW treatment line handling capacity is 200 tons/day. The garbage truck is weighed by the truck scale and then onto the feeding platform. The garbage truck dumps the solid waste directly into the garbage collection room. The garbage storage room is a sealed warehouse. The workers sort out the garbage, like large pieces of furniture, quilts, cotton clothes, decoration of the broken toilet, decorated objects, bottles, pesticide bottles, fluorescent tubes, etc.

The solid waste is then transported from the stocker to the hopper of the plate feeder by the loader, and the plate feeder is placed on the floor. The plate feeder is placed on the second floor. Receiving hopper is made of a 20m3 hopper. The garbage is fed through the plate feeder and the bagged garbage is torn into the hoisting machine. The bagging machine has the function of breaking bags and cloth. Therefore, The feeding of the plate feeder serves as a uniform material to facilitate the smooth operation of the subsequent equipment. In order to environmental sanitation of discharging platform, the upper part of the storage pit can be made automatically open the lid or automatic shutter doors.

The garbage is then sent to the large artificial sorting platform by the belt conveyor. The garbage will be sorted manually, like the bulk of garbage and hazardous waste.

After the manual sorting, the waste is sent to the two-stage rotary drum screener for screening treatment. The sieve plate aperture is 20mm and 60mm. This screener can divide solid waste into less than 20mm, more than 20mm but less than 60mm and more than 60mm of material. The materials that are less than 20mm are mainly sand, usually for landfill processing.

The materials that are more than 20mm but less than 60mm are mainly organic matter. The hanging magnetic separator selected iron (caps, batteries, coins, etc.)in the part of the organic matter. And then it can be into composting. In order to maximize the selection of the battery, we design a magnetic roller for the belt conveyor drive roller. In this way, the mall button batteries in the organic matter can be selected, which will help improve the quality of composting.

The material that is more than 60mm will be sent to an integrated fanning machine. This machine can select heavy material (stone, building garbage, glass, porcelain, hard plastic, textile, shoes, large pieces of organic matter, wood, diapers, etc.) and light material (light plastic, dried leaves, and dry paper, etc.). The selected heavy materials are sorted manually. They select hard plastic, large organic matter and indifferent unburned refuse (stone, construction waste, glass, porcelain, etc.), The remaining substances are combustible materials. They are crushing, drying and extruding to RDF fuel. They can be hard plastic-packaged for sale. Bulk organic matter is transported to the compost areas and composted with organic matter. Indifferent materials are in landfills with sand.

The second step: Composting, organic Waste treatment

Pre-sorted organic matter is transported through the hopper and conveyor to the main fermentation tank. The main fermentation can be carried out in open air or in a fermentation bin, and oxygen is supplied by means of mixing or forced ventilation. The manner of supplying air depends on the type of fermentation tank. The decomposition of the initial fermentation material is carried out at the most suitable temperature for the thermophilic bacteria (growth and breeding temperature of 30 ~ 40 ℃). With the increase in temperature, the bacteria can be the highly efficient decomposition of the supply of oxygen and the degree of good insulation of the stack. And then it will enter the cooling stage. The temperature, rising to the beginning of cooling, is known as the main fermentation period. The main fermentation period of MSW aerobic composting is about 4 ~ 12 days using a compost windrow turner.

When the carbon and nitrogen ratio is too high in the composting, it will lead to soil nitrogen starvation. When the carbon and nitrogen ratio is too low, unserved composting is applied to the soil, which will decompose ammonia, which endangers the growth of crops. Therefore, after the main fermentation of the semi-finished products, it must be in post-fermentation. Post-fermentation can be carried out in the dedicated warehouse, but usually, the material accumulates to 1 ~ 2m height, being in open fermentation. In order to improve the efficiency of post-fermentation, it sometimes still needs to turn or ventilate. The organic materials that have not yet decomposed in the main fermentation process may be fully decomposed at this stage, which becomes into humic acid, amino acids, and other relatively stable organic matter, to be fully mature composting. The post-fermentation time is usually 15 ~ 20 days.

Related Reading: