As we all know, composting can take anywhere from several weeks to a year to complete depending on the method used. Here I would like to introduce WINDROW COMPOSTING–one of the most popular commercial composting technology worldwide.

Windrow Composting Advantages

◆ Windrow composting is a suitable option for manure management, reducing the risks of odor, soil, and water pollution.

◆ Windrow composting becomes economically and technically attractive due to its relatively simple equipment requirements and good performance results, bringing economic and environmental profits.

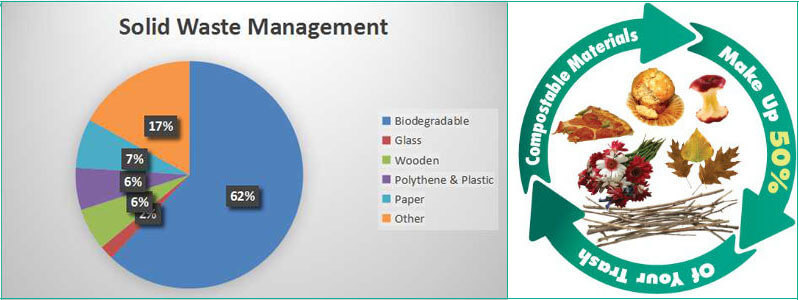

◆ Composting significantly reduces the amount of organic material ending up in landfills, taking the example of Commercial composting at the Iowa City Landfill, about 7,500 tons of organics each year—yard waste, leaves, and some food waste are processed into high-quality compost whose quantity arrives at 2,100 tons.

◆ Windrow composting does require a large amount of land and the leachate produced does have the possibility to contaminate surface and groundwater, but with proper infrastructure both of those concerns are easily handled.

Application of Windrow Composting Method

◆ Windrow composting is suitable for large volumes of organic waste generated by entire communities and collected by local governments, and food processing businesses (e.g., restaurants, cafeterias, packing plants) and can even handle grease and animal byproducts.

◆ Yard waste, paper and cardboard, food waste, water treatment residuals, biodegradable plastics, pallets, sheetrock, and other biodegradable materials are no problem for windrow composting process.

What is Windrow Composting? Windrow Composting Process & Technology

Windrow composting is usually considered to be the most cost-effective composting alternative. Meanwhile, it may also have the highest fugitive emissions.

A hydraulic compost turner is used in the windrow composting process

Windrow composting involves long rows of compost where the actual size and shape of the windrow are dependent on the feedstocks and type of COMPOST TURNER. The piles of materials are placed in long rows and turned by mechanical equipment to maintain optimum conditions. Mechanical turning is usually done with a full hydraulic crawler type turner machine specially designed for turning windrows. The reason for periodically turning the piles is to ensure adequate oxygen flow to the pile.

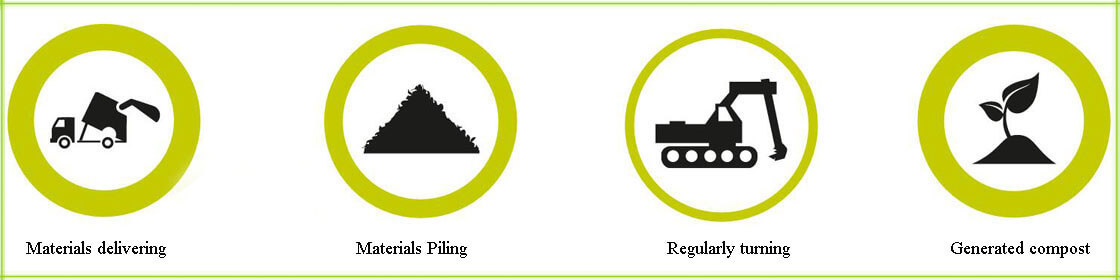

Windrow composting involves a few major steps: Feedstock Preparation, Windrow Processing, and Screening.

Feedstock preparation

–Collection: Organic waste such as green materials and food materials are recyclable through composting. Therefore, the collection becomes the first step for the normal operation of industrial-scale composting facilities. Commercial and farm wastes arrive directly at the composting facility from various sources. Most of the biodegradable residuals and byproducts come from commercial, industrial, municipal, and farm/agribusiness sources. After collecting, these source-separated materials become feedstocks in a commercial composting process that turns organic waste into a valuable resource – compost.

High Moisture Fertilizer Crusher

–Size reduction: Shredding or pulverizing reduces the size of the waste articles, resulting in a uniform mass of material. Grinding the organic material before composting greatly speeds up the composting process. The smaller the size of an organic refuse particle, the more quickly the microbes can consume it. It is accomplished with a semi-wet materials crusher machine. Size reduction is to provide greater surface area for microbes to attack, improve insulation, facilitate homogenizing of initially heterogeneous material, to reduce depth for oxygen diffusion.

–Blending: Materials can be blended and mixed to achieve a suitable C/N ratio. Microbial activity is greatest when the carbon-to-nitrogen ratio (C/N) is 30:1. This can be done easily by mixing equal parts of green and brown materials. Types and volumes of feedstocks are selected to ensure the blended admixture falls within the tolerances of each parameter, ultimately coming together to meet the desired targets for C:N ratios, moisture levels, porosity and homogeneity. In order to ensure a uniform and rapid decomposition, the compost must be thoroughly mixed. Click to see compostable nitrogen-rich materials and carbon-rich wastes

Windrow processing

Windrow composting, employing long narrow windrows mechanically turned by a commercial compost turner on a regular basis, has become the most popular industrial composting method in the world, especially in developed countries such as the United States, Australia, Italy, etc.

commercial compost turner in operation–windrow composting facility

▼ After crushing and blending, the material to be composted is placed into windrows, in the open air. Usually dimensions of the windrow range from 3-12 feet tall and 8-20 feet wide, as long as it could be. The moisture content should be 45-55 percent since poor aeration occurs at higher moisture contents and slow digestion is encountered at lower moisture contents.

▼ Rows are regularly turned to make sure there is enough oxygen for the microbes to work. Frequent turning is the best way to improve compost quality, promote high concentrations of beneficial microbes, prevent excessively high temperatures, and ensure optimum oxygen concentrations. There are many parameters affecting the frequency of windrow turning:

— The size of the composting material and the type of composting structure also affect the frequency of turning.

— If C:N ratio of these two conditions is at an ideal level and mixed well, expect less frequency of turning.

—Turning frequency should normally be based on temperature, and should occur whenever temperatures exceed 140°F or drop below 90°F.

▼It is considered finished when the organic material has fully decomposed and reached a stable state.

Daily windrow composting maintains oxygenation to achieve maximum degradation, irrigation as necessary, and closely monitoring moisture content, and temperature. See more information on Factors Affecting Composting

Outdoor composting in piles that rely on mechanical aeration, typically with a compost windrow turner, to optimize the composting process. Our compost turner machines are very efficient, which makes the whole composting process fast, high-rate, and capable of rapid degradation and stabilization of almost all organic materials.

Grinding and screening of the final compost product

The final step is high-speed grinding, using a chain crusher.

The screening process is to remove non-compostable material from the generated compost and to produce a finer product that meets the requirements of consumers.